Automated palletising solution - StackSmart

Uncompromised quality. Unmatched affordability.

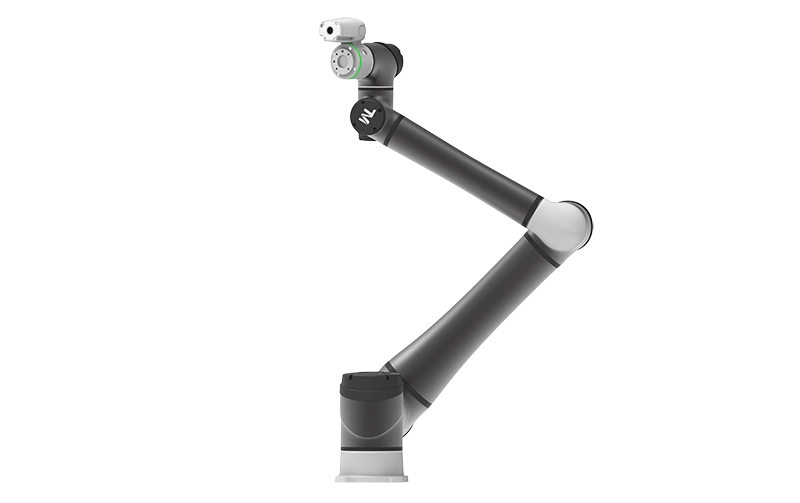

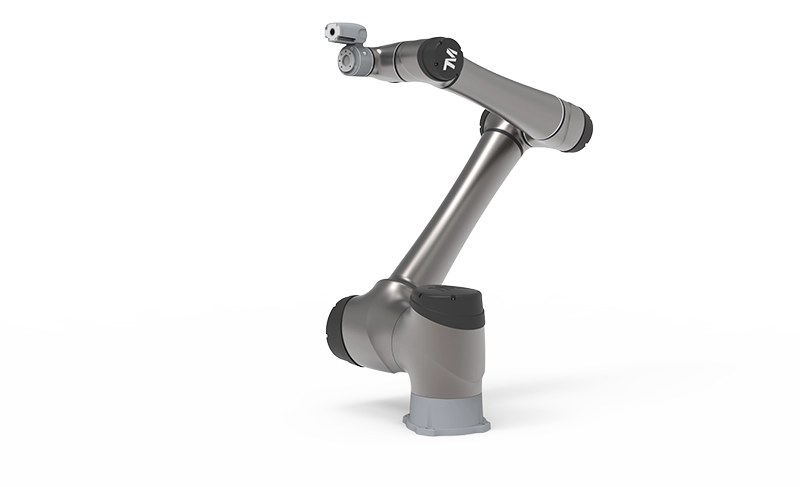

Engineered for efficiency, our powerful and intuitive StackSmart palletising solution effortlessly handles a diverse range of workpieces and production runs. Equipped with industry-leading robots from Techman and end-of-arm tooling with award-winning palletising software from OnRobot, StackSmart delivers unmatched performance while maintaining the highest certified safety standards.

- Payloads up to 35 kg

- Suitable for UK, Euro & custom pallets

- Max. stack height: 2198 mm

- Stacking rate: Up to 12 cycles per minute

- Single & dual-sided pallet stations

- Dual conveyer & dual-sided pallet stations

- Installed and ready to use in one day

StackSmart Palletising Solution from LG Motion - starting at £69,000

The StackSmart palletising solution is a fully automated, ready-to-deploy system designed for rapid integration into your manufacturing line.

Engineered for versatility, StackSmart can be installed in just one day, helping you resolve end-of-line production challenges with lasting efficiency. Capable of handling a range of payloads and pallet heights, StackSmart adapts to various palletising requirements, offering an easy, reliable way to keep production steady, accurate, and streamlined.

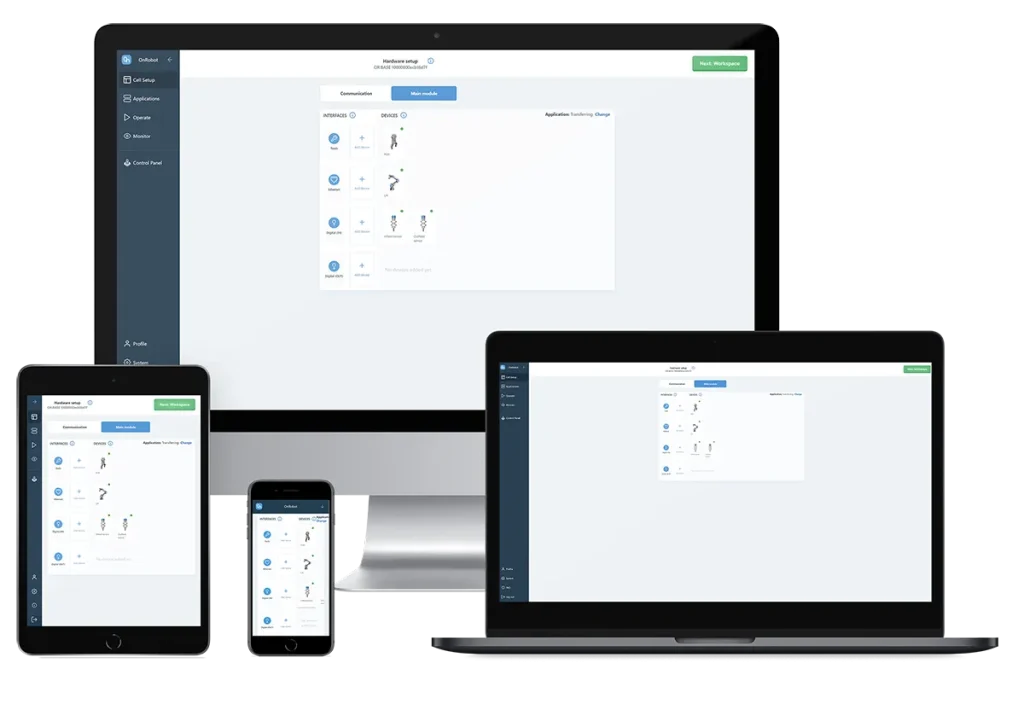

Step 2

Set up D:PLOY and run the application.

D:PLOY simplifies automation to provide you with a flexible, easy and affordable entry point into robotic automation.

- Up to 90% deployment time savings for faster ROI

- Flexible pallet placement, including second pallet for increased productivity

Step 3

Do you require a pallet station?

The pallet station is a mechanical guide for pallets in a pallet application.

The Pallet Station is normally integrated with Lift100 and the Palletising application software with either one or two pallet stations.

Step 4

Do you require a Lift100 to gain an extra axis?

The OnRobot Lift100 is a long-stroke, high-payload robot elevator that adds a versatile seventh axis to six-axis robot arms.

Step 5

Choose your desired OnRobot gripper.

Your solution is now complete!

The automated palletising solution is available from £45,000 *excluding installation

To build your own solution, use our configurator, or contact us using the form at the bottom of this page.

Watch Techman Robot in action

If you’re looking for a cobot specialist in the UK, please get in touch.

We’ll work with you to advise and develop the most appropriate solution.