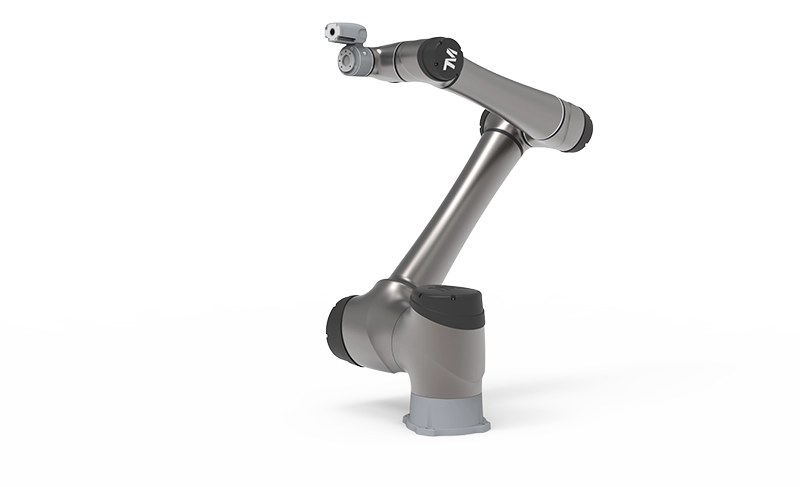

TM30S robot

TM30S

The TM30S excels in high-volume industrial tasks, boasting a 30 kg load capacity and a 1702 mm reach.

Under a palletising scenario, the maximum payload capacity is 35 kg. Its durable, lightweight design ensures optimal performance in heavy-duty settings such as push stacking, machine tool material handling, and automobile assembly. this model enhances efficiency and safety with TÜV-certified functions, and offers superior handling and manoeuvrability for faster, reliable operations.

Regular payload

Reach – 1702 mm

Payload – 35 kg

Weight – 80.6 kg

Regular payload

Reach – 900 mm

Payload – 4 kg

Weight – 22.6 kg

TM AI S Series

FASTER

25% faster cycle time!

• The joint speed of the 6th axis is increased from 225 °/s to 450 °/s

• Reduces the cycle time of your production line by 25%* for improved efficiency

MORE PRECISE

Best cobot repeatability of ±0.03 mm!

• Delivers up to a 70%* increase in repeatability accuracy of ±0.03 mm

SMART ROBOTICS

Built-in AI vision

AI-powered robots recognise the presence and orientation of their environment and parts to perform visual inspections and dynamic pick-and-place tasks. Effortlessly apply AI to the production line and increase productivity, decrease costs, and shorten cycle times. AI vision can also read results from machines or test equipment and make appropriate decisions accordingly.

- Automated optical inspection (AOI)

- Quality assurance & consistency

- Increase production efficiency

- Reduce operating costs

Besides improving automation processes, an AI-driven robot can track, analyse, and integrate data during production to prevent defects and improve product quality. Easily enhance your factory automation with a complete set of AI technology.

A true vision leader

Techman robots are equipped with an integrated vision system, giving robots the ability to perceive their surroundings which significantly enhances robot capabilities. Robot vision or the ability to “see” and interpret visual data into command prompts is one of the features that makes us superior. It is a game-changer for accurately performing tasks in dynamic changing workspaces, making operations run smoother, and automation processes more efficiently.

SIMPLE ROBOTICS

Painless programming

The robots come with “TM flow”, an innovative flow-based robot editing software that allows you to complete any industrial program in simple actions, just click and drag without any coding experience!

- Graphical interface for easy programming

- Process-oriented editing workflow

- Simple hand guiding for positions teaching

- Fast visual calibration with calibration board

Flexible connectivity

The Techman series interfaces with a variety of communication solutions, allowing you to connect your industrial networks together. It also allows for a wide selection of grippers for your specific process needs.

SAFE ROBOTICS

Safe collaboration

Clever and safe design specification that allows the cobots to work with your team in the factory. When the robot collides with an object or person, it immediately stops any actions to prevent doing harm.

- Complies with ISO 10218-1:2011 & ISO/TS 15066:2016

- Collision detection with emergency stop

- Save the cost and space for barriers and fencing

- Set up speed limits in a collaborative workspace

Watch Techman Robot in action

If you’re looking for a robot specialist in the UK, please get in touch.

We’ll work with you to advise and develop the most appropriate solution.