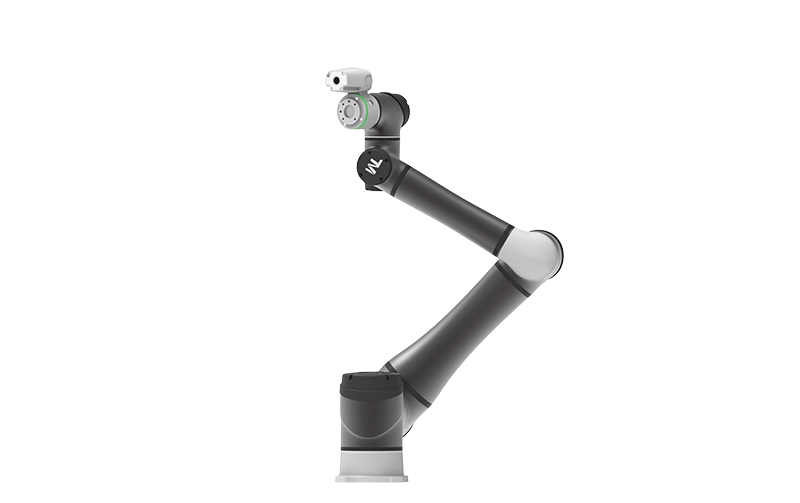

Techman Robot – Alarm testing application from Absolute Robotics

Optimising testing and quality control with Techman Robot

In today’s fast-paced industrial landscape, the importance of testing and quality control cannot be overstated. Companies are increasingly turning to automation solutions like Techman robots to enhance their testing processes, ensuring that products meet the highest standards of quality. Below we’ll explore the advantages of using Techman Robot for testing applications, highlighting key features, suitable industries, and a compelling case study from Absolute Robotics.

Why choose Techman robots for testing and quality control?

Techman Robots stands out in the market for several reasons. Their collaborative design, user-friendly interface, and versatile capabilities make them an ideal choice for various testing applications:

- Collaborative functionality: Techman robots are designed to work alongside human operators, enhancing productivity while ensuring safety.

- Precision and reliability: Techman robots deliver consistent performance, ensuring that each testing cycle produces accurate results.

- Flexible integration: These robots can seamlessly integrate into existing production lines, allowing businesses to automate testing without major disruptions.

- Ease of use: The intuitive programming interface allows for quick setup and operation, reducing the time needed for staff training.

Key features of Techman robots in testing and quality control processes

When it comes to testing and quality control, several features of Techman robots stand out:

- Vision systems: Equipped with advanced vision technology, Techman robots can identify and assess products, ensuring that only items meeting quality standards proceed to the next stage.

- Multi-tasking capability: Techman robots can perform various tasks within the testing process, from inspection to packaging, streamlining operations and reducing labour costs.

- Real-time data collection: The ability to collect and analyse data in real-time enhances decision-making and improves overall efficiency.

Suitable industries for testing and quality control applications

The application of Techman robots in testing and quality control is versatile, making them suitable for various industries, including:

- Electronics: Ensuring that components function correctly before assembly.

- Pharmaceuticals: Verifying the integrity and quality of packaging and products.

- Automotive: Testing parts for durability and compliance with safety standards.

- Consumer goods: Conducting quality checks on a wide range of products, from appliances to toys.

Alarm testing application at Absolute Robotics

A great example of Techman robots in action is the alarm testing application implemented by Absolute Robotics. In this setup, alarms are delivered to the robot via a conveyor system. Here’s how the process works:

- Receiving alarms: The robot receives alarms from the conveyor, initiating the testing process.

- Testing: Using its precision, the cobot places the alarm into a mount and tests the functionality of each alarm.

- Fitting covers: Once tested, the robot fits a cover onto the back of the alarm, ensuring it’s ready for packaging.

- Conveyor transfer: Finally, the robot places the completed alarms onto another conveyor for packing, streamlining the workflow.

This application not only enhances the quality control process but also improves efficiency and reduces human error, demonstrating the power of automation in testing environments.

Techman Robot – Alarm testing application demonstration video

Contact us or buy online

If you’re looking for a cobot specialist in the UK, please get in touch.

We’ll work with you to advise and develop the most appropriate solution.